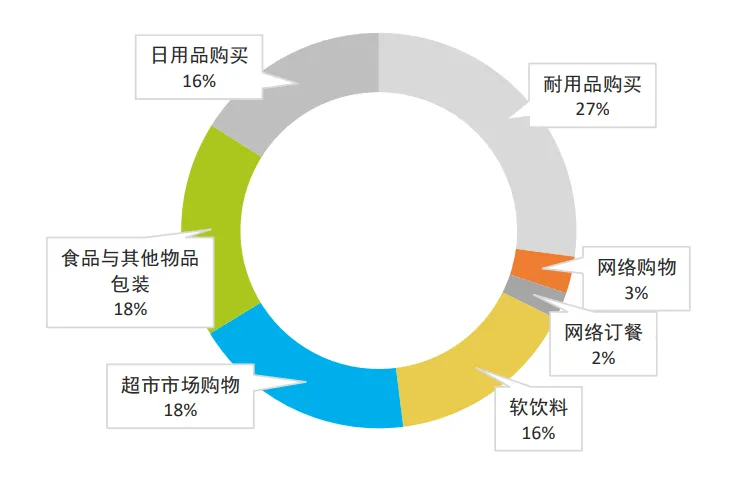

Studies have shown that the plastic industry consumes 8% of the world's oil, and about 38% of plastics in our country are used for packaging, with food and beverage-related plastic packaging being the focus of consumption.

Have you ever been attracted by the packaging of a product and made a purchase? The importance of packaging to products is self-evident. However, with the booming development of the packaging industry, the permanent waste generated by the use of non-degradable plastics and excessive packaging has brought a serious burden and harm to the ecological environment.

Moreover, the production and disposal of plastics also bring a large amount of carbon emissions. Taking the common PET beverage bottle as an example, the emission of a 500mL cola bottle is about 60.48 grams of carbon dioxide equivalent, and the emission of cola packaging sold nationwide in one year can reach nearly a million tons.

However, in recent years, with the concept of low-carbon environmental protection gradually taking root in people's hearts, more and more people choose green lifestyles and consumption methods, and green packaging is favored by the market.

01 What is Green Packaging

Green packaging refers to packaging that has a small impact on human health and the ecological environment, and consumes less resources and energy during the entire life cycle of the packaged product while meeting the functional requirements of packaging.

Generally speaking, green packaging should comply with the 3R1D principle, that is, packaging reduction (Reduce), reusable (Reuse), recyclable (Recycle), and degradable (Degradable).

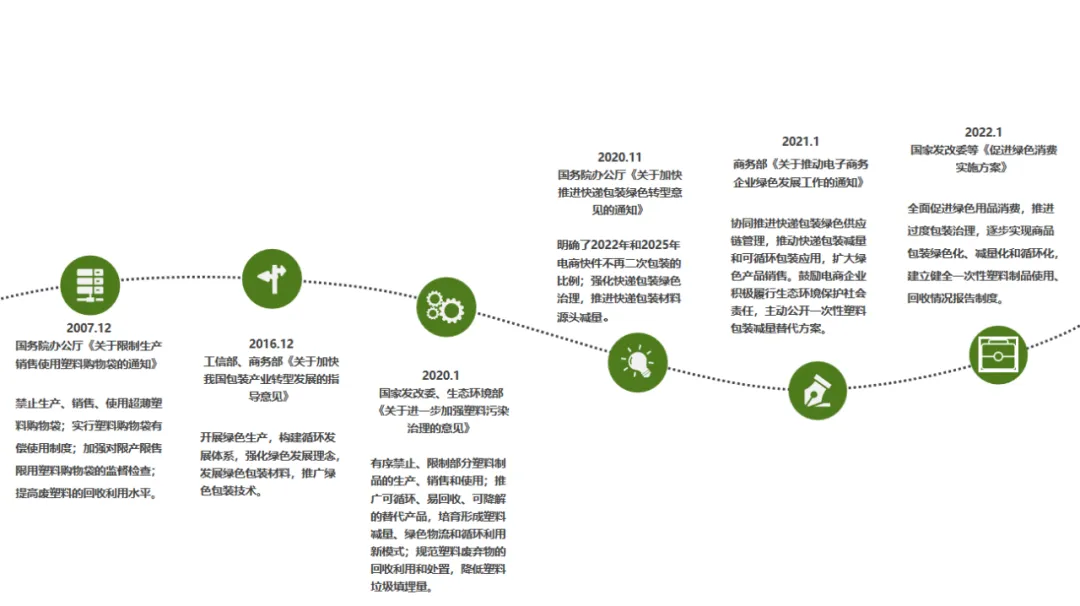

In recent years, our country has made positive efforts in the field of green packaging. The "plastic restriction order" was promulgated and implemented in 2007, and an upgraded "plastic restriction order" was introduced in 2020. With the rapid development of e-commerce logistics in recent years, policies and standards related to reducing plastic use, eliminating excessive packaging, and recycling packaging have been密集ly issued.

Figure: Some of the policies and regulations related to green packaging in our country | Source: Carbonstop collated from public information

Figure: Some of the standards related to green packaging in our country | Source: Carbonstop collated from public information

02 How to Reduce Plastic and Carbon in Food and Beverage Packaging

Food and beverage packaging is one of the main application fields of plastics. As a packaging for food and beverages, its role is to protect food from external air, light, moisture, microorganisms, and other factors, and to maintain the stability of food performance. Plastic packaging is widely used because of its light weight, high strength, strong corrosion resistance, and low cost.

According to statistics, Chinese families consume an average of 86 kilograms of plastic per year, of which 82 kilograms are bulk consumption, and food and beverage-related plastic packaging accounts for 34% of it.

Figure: The composition of Chinese family plastic consumption (bulk consumption) | Source: "China's Plastic Environmental Footprint Assessment"

Although plastic food and beverage packaging has many advantages, its production process consumes a large amount of fossil fuels, and the recycling of discarded plastics is difficult, and it is difficult to degrade, causing white pollution and bringing a great burden to the ecological environment. Therefore, the production and use of plastic packaging are increasingly restricted.

Packaging Materials: Vigorously develop ecological packaging materials

Ecological packaging materials refer to packaging that is harmless to the ecological environment and human health, has energy recycling and material recycling, and promotes sustainable development.

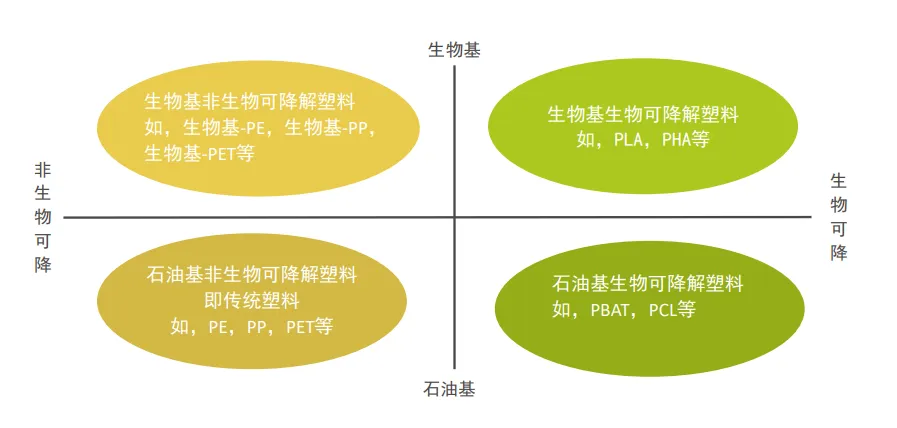

Among them, the representative is degradable plastic. Degradable plastics are made by adding a certain amount of additives (such as starch, modified starch, or other vitamins, photosensitizers, biodegradants, etc.) during the production process, which reduces their stability and makes them easier to degrade in the natural environment.

Plastic can be divided into degradable plastics and non-degradable plastics according to whether the plastic can degrade; according to the source of raw materials, plastics can be divided into bio-based plastics and petroleum-based plastics.

Figure: Classification of degradable plastics | Source: "China's Plastic Environmental Footprint Assessment"

In the field of food and beverage packaging, bio-based degradable plastics represented by polylactic acid (PLA) and petroleum-based degradable plastics represented by polybutylene adipate (PBAT) have been widely used, such as the PLA straws we see in some milk tea shops.

Figure: Biodegradable polylactic acid (PLA) straws | Source: Haizheng Biology official website

Packaging Design: Paper instead of plastic, lightweight design

By using paper instead of plastic, lightweight design, and other methods, increase the use of green packaging in the field of food and beverage. For example, pulp molded packaging, whose raw materials are mostly plant fibers such as sugarcane渣, bamboo渣, etc., the material is pure natural and degradable, and the amount used is relatively less than traditional packaging, and is widely used in gift boxes such as tea, mooncakes, egg trays, lunch boxes, and other fields.

Carbonstop, in conjunction with innovative packaging ecological partners in the industry, has developed pulp molded packaging products through several months of research and development, giving packaging a carbon footprint from then on.

Figure: Pulp molded packaging

Packaging Recycling: Build and improve the recycling system

From the perspective of packaging recycling, by recycling and recycling packaging, the service life of packaging is extended, thereby reducing the number of packaging waste.

At present, many food and beverage brands, packaging manufacturers, and takeout express platforms are actively building and improving the packaging recycling system to promote the recycling of packaging.

For example, Morning Light, in conjunction with Meituan Green Mountain Plan, used recycled lunch boxes to make recycled plastic, and launched the first carbon-neutral stationery series, which appeared at the 2023 Boao Asia Forum Annual Conference. Carbonstop completed the carbon accounting and carbon emission offset for the series and issued a carbon-neutral certificate for it.

Figure: Morning Light carbon-neutral stationery made from recycled lunch boxes | Source: Pexels

03 Leading Enterprise Cases

With the concept of green consumption deeply rooted in people's hearts, many food and beverage companies, packaging manufacturers, and takeout platforms with a sense of social responsibility have begun to promote the use of green packaging. So what are some innovative designs and clever ideas for green packaging?

Food and Beverage Brands

Coca-Cola

Coca-Cola proposed the "World Without Waste" sustainable packaging strategy. It responds to the plastic waste crisis from the dimensions of packaging design (such as increasing the use of recycled materials) and packaging recycling (building a recycling system).

In July 2022, Coca-Cola's mineral water brand Dasani launched a packaging bottle made of 100% recycled PET plastic (100%rPET) in North America.

Figure source: Coca-Cola official website

Yili

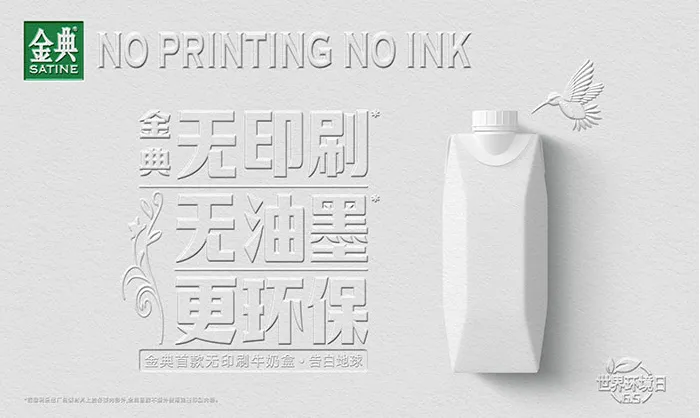

As a dairy brand, Yili's product packaging is mainly paper-based composite packaging. Yili reduces the carbon emissions of packaging by purchasing certified packaging materials, using renewable materials, and actively guiding the practice of waste packaging recycling activities.

In June 2022, Yili Jin典's first no printing, no ink packaging, the packaging uses the production process of Yili Jin典's first recycled milk box, achieving self-circulation.

Figure source: Yili official website

Nestle

Nestle has set a goal to achieve 100% recyclable or reusable packaging by 2025; to reduce the use of virgin plastic by 1/3 by 2025.

In January 2023, Nestle's candy brand Qi K巧 launched a recyclable packaging paper to reduce plastic use, which will be piloted first in Australia.

Figure source: Nestle official website

Packaging Manufacturers

Amcor

Amcor is a global consumer packaging company, achieving packaging sustainability by using recycled resins, lightweight packaging design, and introducing bio-based materials.

Amcor AmPrima™ PE Plus launched a recyclable drink, puree, and sauce bag solution.

Figure source: Amcor official website

Fenmei Packaging

Fenmei Packaging is a domestic liquid food aseptic packaging supplier, with main products including brick packs, diamond packs, pillow packs, etc., and the packaging material is mainly paperboard. Fenmei Packaging further improves the sustainability of packaging by responsibly purchasing raw materials and reducing the use of petroleum-based plastics.

To reduce the use of petroleum-based plastics, in 2021, Fenmei Packaging launched a more environmentally friendly Greatview® Planet, which mixed bio-based polyethylene into the polyethylene material.

Figure source: Fenmei Packaging "2021 Sustainability Report"

Takeout Platforms

Meituan Takeaway

As a takeaway platform, Meituan Takeaway launched the first environmental protection action plan in the takeaway industry in 2017 - Green Mountain Plan. The plan proposed the next stage goal in 2020, intending to promote the sustainable transformation of the takeaway industry by building a green packaging supply chain, promoting the construction of recycling and recycling marketization mechanisms, and strengthening consumer guidance and incentives.

Meituan Green Mountain Plan, in conjunction with packaging manufacturers, has developed pulp molded lunch boxes for takeaway meals. Encourage consumers to choose not to use disposable tableware. After Carbonstop accounting, not using disposable tableware on the Meituan takeaway platform each time can reduce carbon by 38 grams.

Figure source: pexels

04 Carbonstop Opinion

Start from the tip of the tongue, let "white pollution" wear a "green new coat"

In response to "white pollution" and achieving carbon neutrality, leading food and beverage companies have given their own solutions. Carbonstop believes that the food and beverage industry can achieve plastic reduction and carbon reduction, and every company and every person can make their own contribution.

As consumers, you can:

Try to dine in to reduce the use of plastic packaging and disposable tableware;

Bring your own tableware, when ordering takeout, choose "no tableware";

When purchasing food and beverages, prioritize paper packaging or other green packaging products;

If conditions permit, bring your own cup to buy drinks such as coffee, saving money and being environmentally friendly;

Precise garbage classification, consciously fulfill the obligation of domestic waste classification and disposal.

As food and beverage or packaging manufacturing companies, you can:

Carry out carbon accounting for products or product packaging to create low-carbon or carbon-neutral products and establish a green corporate image;

Promote energy-saving transformation in the production process and low-carbon construction of the supply chain to achieve low-carbon sustainable development at the corporate level;

Actively develop innovative products such as pulp molded packaging to replace plastic packaging, making the material source more low-carbon and easier to degrade;

Innovate packaging design to make packaging lighter and reusable;

Establish a waste packaging recycling system to explore packaging recycling and reuse models, and practice corporate social responsibility.