Challenges and Difficulties in Carbon Footprint Data Collection and Model Building

1. Strict Calculation Method Requirements

Unlike ISO 14067 or PAS2050, the EU's new Battery Regulation stipulates that data collection and modeling calculations for batteries should follow the Product Environmental Footprint (PEF) method. To this end, the EU issued a draft for calculating the carbon footprint of battery products at the end of 2023, and further solicited opinions in April 2024.

According to the calculation guidelines provided by the EU (taking power batteries as an example), the production of components such as anodes, cathodes, electrolytes, casings, and cooling systems, as well as the production of cells, battery packs, and modules, all require modeling based on actual production data. These requirements significantly increase the quality of data required, making data collection more difficult and model building more complex and challenging.

2. Increased Difficulty in Data Collection

1. Diverse Supplier Base

Battery manufacturers not only produce necessary components in their own factories but also often procure anodes, cathodes, electrolytes, casings, and cooling systems from multiple suppliers. According to the calculation guidelines, each component supplied by each supplier requires on-site investigation and collection of actual production data. For example, if a battery model has 6 components, and each component has 3 suppliers, then 18 sets of actual data need to be collected, greatly increasing the difficulty of data collection.

2. Rich Variety of Battery Models

Battery manufacturers often produce various models and types of batteries. Each type of battery requires on-site data collection for modeling. If a manufacturer produces 2 types of battery products, the difficulty of on-site data collection will be twice that of the base case.

3. Complex Upstream Supply Chain

The battery industry supply chain is complex, especially in the upstream supply chains of anodes, cathodes, electrolytes, casings, and cooling systems. Taking electrodes as an example: modeling requires collecting production and transportation information for raw materials and auxiliaries such as active substances, aluminum foil, copper foil, binder, NMP, and other chemical reagents. Each type of raw material may involve multiple suppliers, further increasing the difficulty of data collection. Additionally, there are differences in management systems and data management levels among upstream suppliers, adding uncertainty to data collection.

3. Challenges in Model Building

1. Lack of Baseline Background Data

In carbon footprint modeling, current practices mainly rely on international databases such as ecoinvent, which are expensive; or software like Gabi, SimaPro, and Carbonstop's Carbon Cloud, which link to various databases. These restrictions create barriers for companies and incur high economic costs.

Research and data foundations for battery product carbon footprints are limited. Taking electrodes as an example, when collecting actual production data for electrode production and building models, background data models for various raw materials and auxiliaries, such as active substances, aluminum foil, copper foil, binder, NMP, and other chemical reagents, are needed. These background data are difficult to obtain through public channels. Moreover, existing databases have some drawbacks, such as outdated data, geographical locations in Europe or the US, and lack of transparency and technical representativeness. These issues require us to actively develop background databases and collaboratively promote the creation of a baseline database that meets the needs of Chinese companies and the actual development of the Chinese battery industry.

The EU's new Battery Regulation stipulates that the Life Cycle Data Network (LCDN the European Platform on LCA) should be prioritized.

- When the LCDN contains background data with a technical representativeness score ≤4, select the most technically representative or those with a data quality composite score ≤2;

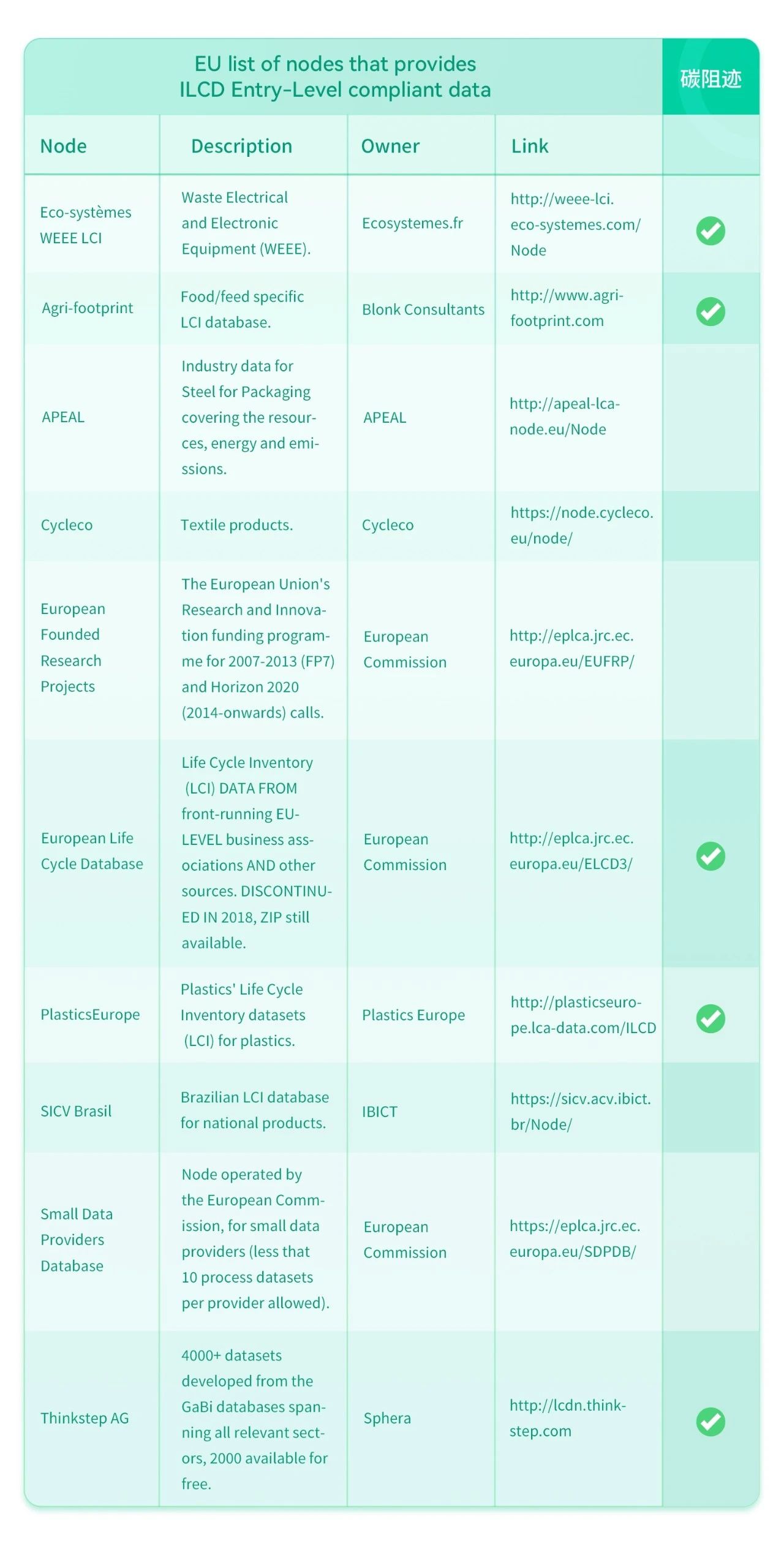

- When the LCDN does not contain background data with a technical representativeness score ≤4, select those with a data quality composite score ≤3, and choose according to the following order: 1) the most technically representative in the LCDN; 2) representative data from other databases (complying with EU Environmental Footprint standards); 3) representative data from databases complying with ILCD entry-level standards. The table below provides nodes and ports that meet the ILCD entry-level data standards:

2. Difficulty in Physical Segregation of Energy and Material Consumption

It is difficult to physically segregate the use of materials, electricity, steam, and other energy-consuming agents, which greatly increases the complexity of energy modeling. The main reasons include: first, manufacturers plan production in different factories based on market demand, with different layouts for different battery models; second, factories arrange production schedules based on orders, meaning that even batteries of the same model may not be produced continuously; third, according to measurement management requirements, only factories and equipment with energy consumption reaching a certain scale need to be equipped with tertiary metering tools, so in most cases, only primary and secondary energy consumption data can be used for preliminary estimation and conversion. Furthermore, companies need to strengthen their energy management system awareness and address the lack of digital energy management platforms, with varying levels of digital management. All these factors greatly increase the difficulty of the modeling process.

3. Complexity in Integrating Overall Models

The final model for batteries needs to integrate models of components such as anodes, cathodes, electrolytes, casings, and cooling systems. During integration, data sets from multiple suppliers must be modeled and quality balance ensured, placing high demands on the overall architecture, data sets, and reference flows of the model.

Comparison Between the Draft and the Consultation Document

The carbon footprint of electricity differs from grid emission factors, as it covers the entire lifecycle of carbon emissions from production to transmission to use. To reduce the carbon footprint of electricity, efforts must be made on the generation side and its upstream, transmission and distribution sides, and the consumption side.

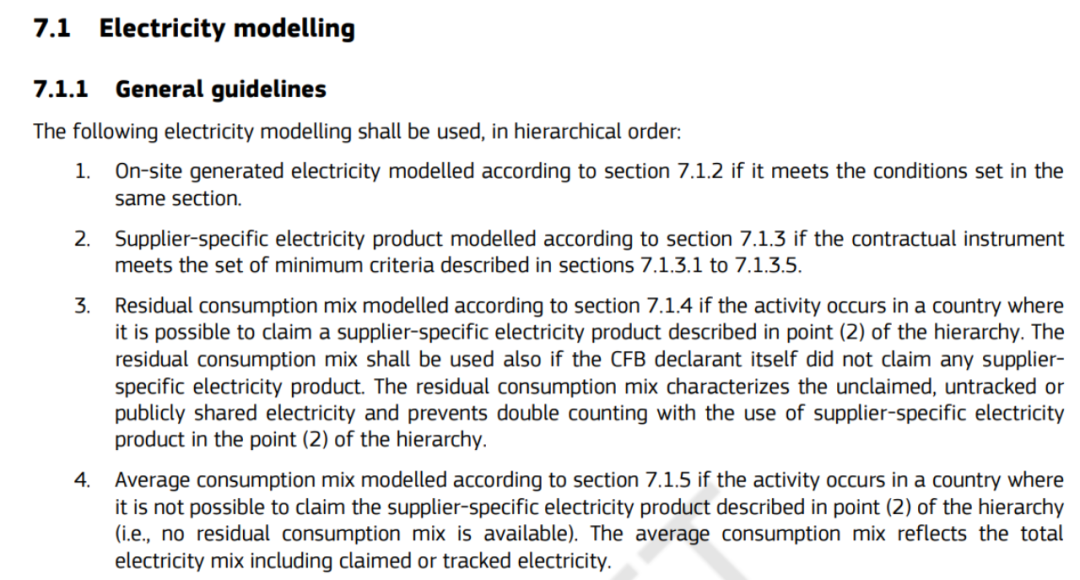

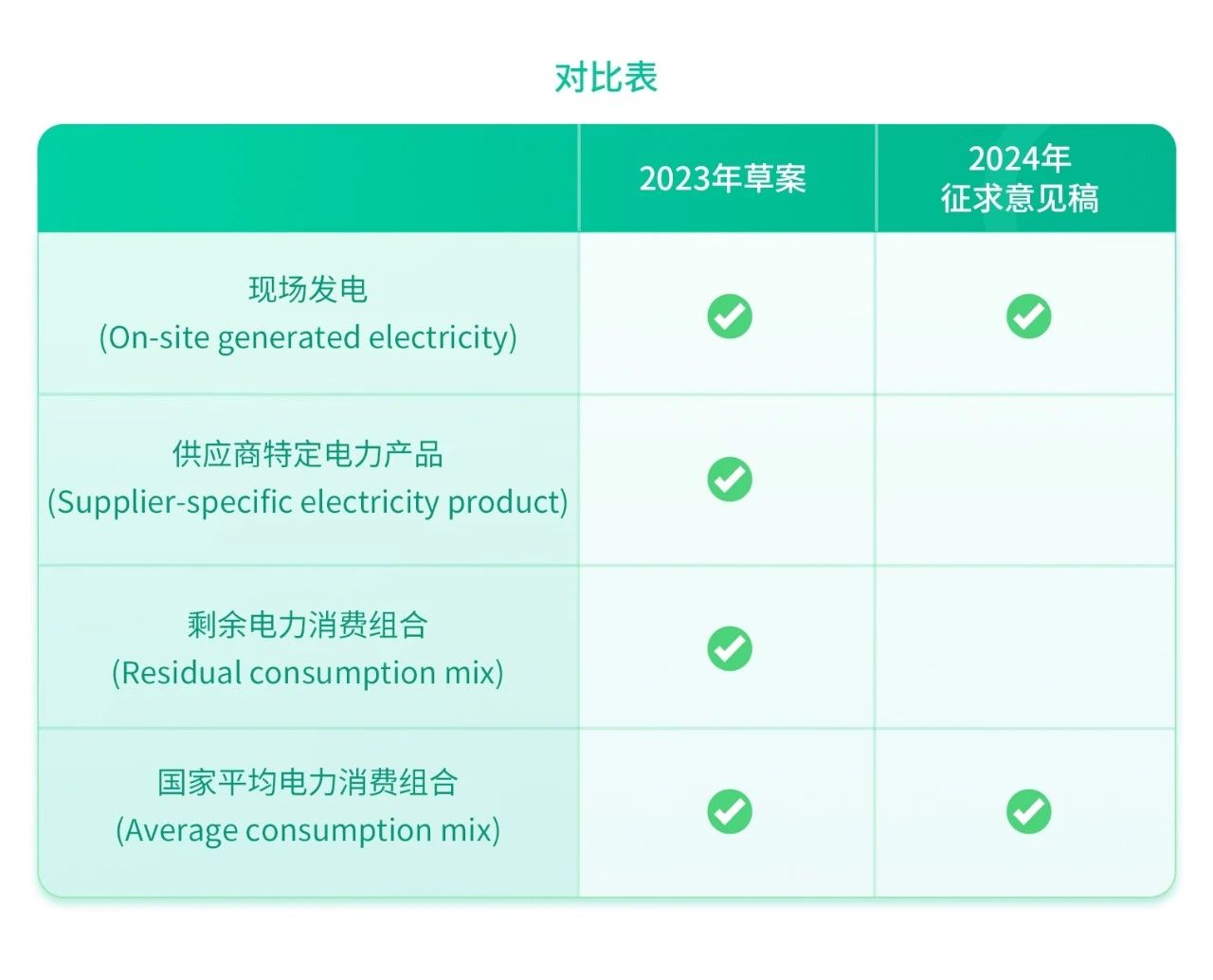

The 2023 draft stipulated the priority order for electricity modeling as follows: on-site generation, supplier-specific electricity products, residual electricity consumption mix, and national average electricity consumption mix. This means that companies could adopt the "grid-supplied electricity using residual emission factors" and offset by purchasing PPAs and green certificates in their electricity carbon footprint modeling.

2023 Draft - Electricity Modeling

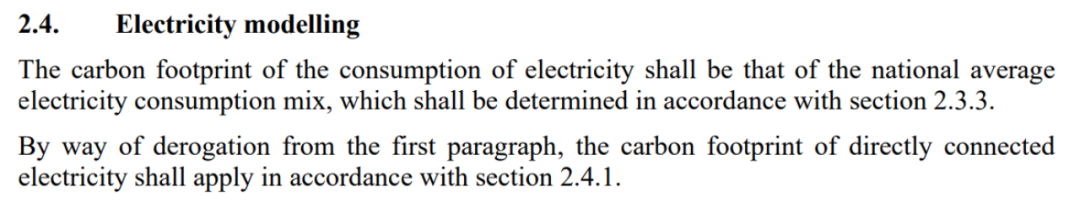

The 2024 consultation document stipulates that the carbon footprint of electricity can only default to the national average electricity consumption mix, and actual electricity carbon footprint can be used for direct power supply within the same facility boundary within the factory. This means that battery products produced in countries with lower national average electricity consumption mix emissions will have a lower electricity carbon footprint. In the future, if companies must meet EU carbon footprint grades and thresholds, they may relocate production bases to countries with lower electricity carbon footprints.

2024 Consultation Document

By comparison, the 2024 consultation document has removed supplier-specific electricity products and residual electricity consumption mixes, retaining only the national average electricity consumption mix and on-site generation, and further clarifying that on-site generation refers to direct power supply within the same production facility boundary within the factory. The removal of supplier-specific electricity products is significant, meaning that non-direct connected parts of China's green electricity and green certificate products are excluded, but direct-supplied park wind and solar power, rooftop photovoltaics, etc., still retain their advantages.

Verification Details Need to Be Improved, Verification Bodies Not Yet Determined

1. Regarding Verification Details

Currently, there is no news or notification confirming the release of verification details. According to the verification section of the 2024 consultation document, verification must adhere to systematic, orderly, and comprehensive principles and cover the following content:

- The carbon footprint model used in the calculation;

- Cut-off points in the modeling, any resulting mass balance gaps, and an explanation of which activity data or dataset the missing mass belongs to;

- The functional unit and all information required to calculate the functional unit;

- Necessary actual data sets;

- All auxiliary background data sets or company-specific actual data sets used;

- Details on how the electricity carbon footprint was determined;

- Detailed information about recycled components and end-of-life models.

2. Regarding Verification Bodies

Based on information available on the EU's official website, there is no confirmation yet regarding the determination of verification bodies for the EU Battery Regulation. According to the verification section of the 2024 consultation document,only the responsibilities of “Notified Bodies” have been clarified, without mentioning other entities. Specifically, the following points are noted:

(1) Notified Bodies shall evaluate whether the declared carbon footprint complies with the requirements set out in this Annex. They shall verify that:

- The data and information used to calculate the carbon footprint are consistent, reliable, and traceable;

- The calculation results are correct.

(2) The evaluation shall include a review of the carbon footprint study report and its publicly available version, and, where appropriate, a review of the model used to calculate the carbon footprint:

- The manufacturer’s facilities

- Battery, cathode, and anode production sites;

- Cathode active material production sites;

- Anode active material production sites;

- One or more other production sites where company-specific actual data were collected, if considered important by the carbon footprint study guidelines.

(3) Notified Bodies shall verify the following and determine whether higher-than-expected uncertainties affect the total carbon footprint:

- All auxiliary data sets used in the model are appropriate and meet the requirements set out in this Annex;

- All company-specific data used in the model are appropriate, meet the requirements set out in this Annex, including: ① data coverage, precision, completeness, representativeness, consistency, reproducibility, source, and uncertainty; ② credibility, quality, and accuracy of the data; ③ quality and accuracy of the underlying documentation.

- The rules for simulating electricity usage specified in this Annex have been correctly applied;

- The accuracy and reliability are acceptable and meet the requirements;

- The conversion of measurement units is correct;

- The estimation methods are appropriate and consistently applied.

According to the EU's official definition of “Notified Bodies,” Notified Bodies are organizations designated by EU member states responsible for assessing the conformity of certain products before they are placed on the market. These bodies perform tasks related to conformity assessment procedures under applicable law when third-party involvement is required.Therefore, it is clear that Notified Bodies and third-party bodies are not entirely the same entities.

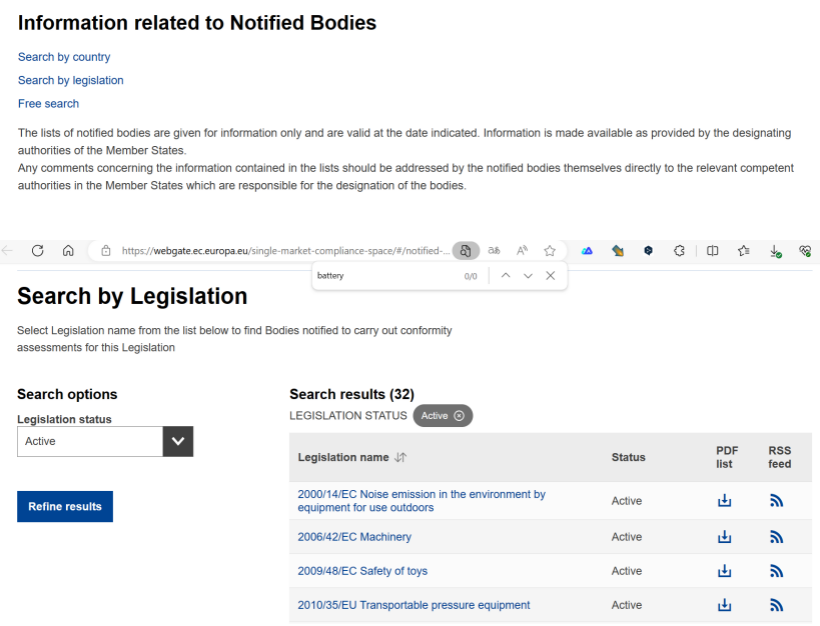

- Method 1: Query through the Notified Body List:

Based on the Notified Body List, there is currently no information available regarding the list of Notified Bodies for the EU's new Battery Regulation.

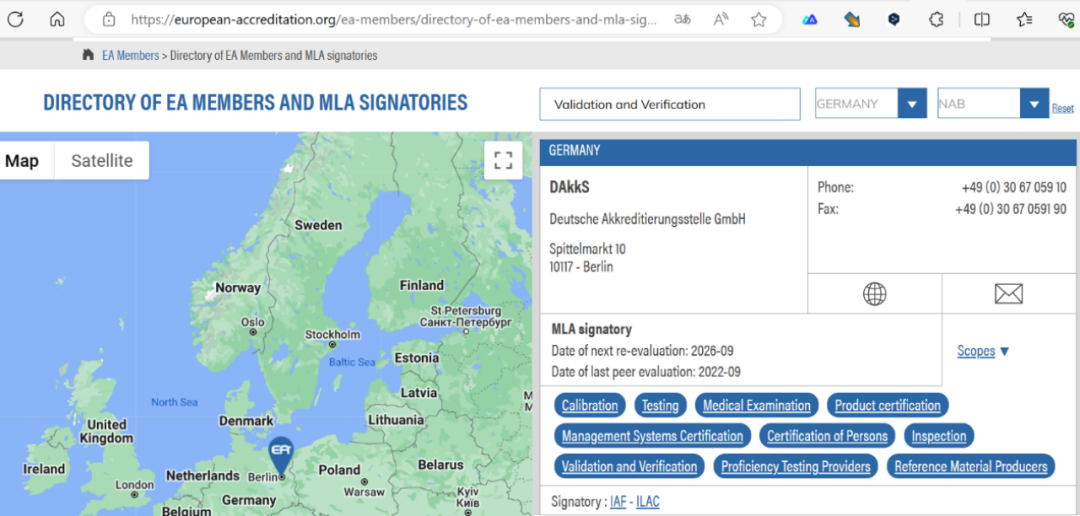

- Method 2: Query through the EU Accreditation and Certification Official Website:

- Select “Verification and Certification Accreditation,” then choose an EU member state. After completing the first step, you can access the official websites of authorized bodies in each member state (the following example uses Germany):

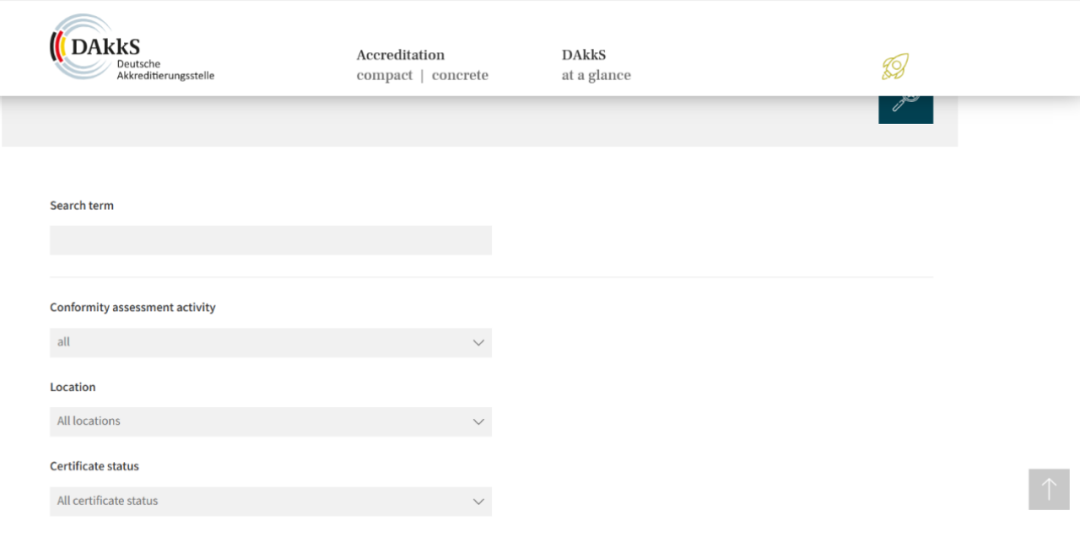

Enter the website of the German Federal Office for Accreditation (Deutsche Akkreditierungsstelle, DAkks), which is responsible for issuing various accreditation credentials to ensure that testing, inspection, and certification bodies' assessment services are trusted across various market sectors. Only institutions accredited by DAkkS are competent to perform designated tasks in accordance with international applicable standards, regulations, and relevant provisions.

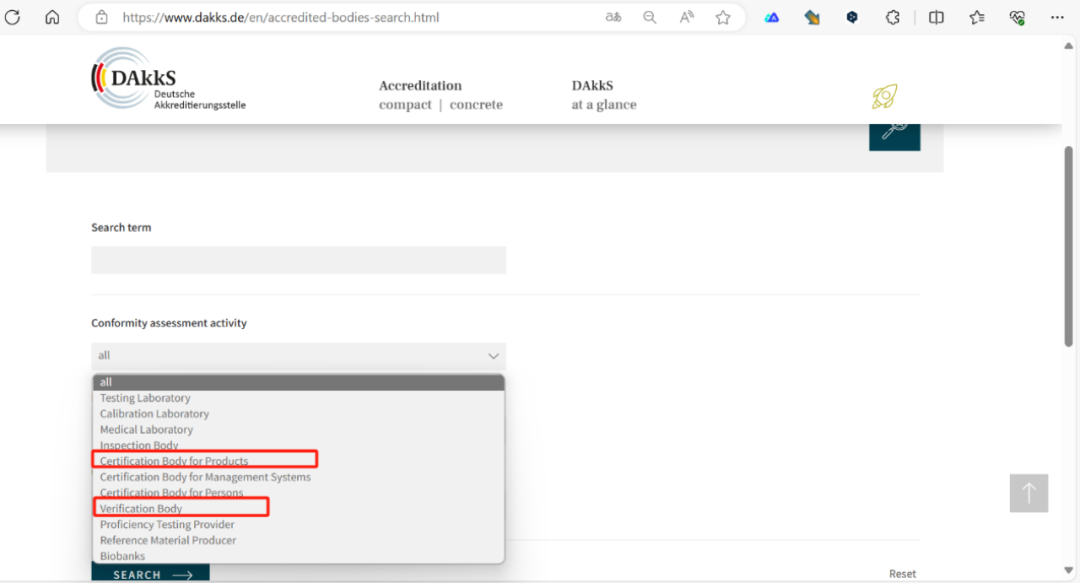

From the DAkks website, information about assessment bodies can be queried through conformity assessment activities (Conformity assessment activity), geographical location, and certificate status. By selecting from the dropdown options, you can see the scope types of authorized conformity assessment activities, as highlighted in red in the figure below.

However, according to the definitions of verification and certification accreditation and certificate issuance provided by the DAkks website, neither applies to the EU's new Battery Regulation. The relevant international standard for “product, process, or service certification” is DIN EN ISO/IEC 17065.

Verification and certification accreditation apply to the EU Emissions Trading System, with the relevant standard being DIN EN ISO 14065.

In summary, through both Method 1 and Method 2, it is further explained that, based on the information currently available on the EU's official website, apart from the explicit mention of “Notified Bodies” in the 2024 consultation document, no other entities such as “third-party bodies” or “verification bodies” have been mentioned.