With the implementation of the EU Green Deal ("European Green Deal") and "Fit for 55," the EU's socio-economic development is accelerating its own green transformation while setting higher entry requirements for companies exporting to the EU1. Under this policy framework, laws and regulations such as the EU Carbon Border Adjustment Mechanism (EU CBAM) and the new battery law have been successively implemented, posing significant challenges for carbon emission accounting and management, as well as carbon information disclosure and verification for exporting companies. Especially for "new three categories" represented by new energy vehicles, lithium batteries, and photovoltaic products, their rapid development and competitive advantages have raised concerns and suppression from European and American countries, making it even more critical to prudently and properly address sustainable development compliance requirements, systematically identify related risks and opportunities, to mitigate the negative impact of "green barriers."

Interpretation of Relevant EU Green Policies

In the green policies related to companies exporting to the EU, the key policy combinations closely related to battery manufacturers are the "EU Battery and Waste Battery Regulation" and the "Sustainable Product Eco-design Regulation."

Overview of Relevant EU Regulations and Key Points:

The "EU Battery and Waste Battery Regulation": Hereinafter referred to as the "New EU Battery Regulation," which came into effect in August 2023. This regulation is a key pillar of the Circular Economy Action Plan under the European Green Deal, covering all types of batteries, requiring batteries entering the EU market and products containing batteries to provide full lifecycle carbon footprint declarations.

➡️ From 12 months after the effective date of the carbon footprint authorization act, the carbon footprint declaration for electric vehicle batteries becomes a mandatory disclosure requirement. If Chinese new energy vehicles and power battery products with global competitiveness fail to provide relevant certification at that time, they will be unable to enter the EU market.

➡️ By February 18, 2027, the mandatory adoption of battery passports will be required; products without a "passport" will not be allowed to enter the EU market.

The "Sustainable Product Eco-design Regulation": Hereinafter referred to as ESPR, which came into effect on July 18, 2024. This regulation is an important tool for the EU's circular economy plan, applicable to all products, components, and intermediate products sold in the EU market. Currently, it has been clearly specified that 11 product categories2 must be accompanied by a "Digital Product Passport (DPP)" when sold in the EU, including communication and other electronic products.

(I) New EU Battery Regulation

The New EU Battery Regulation is the EU's first legal document regulating the entire lifecycle of batteries, covering stages of battery production, use, reuse, and recycling, applicable to all electric vehicle (EV) batteries, light mobility transport (LMT) batteries, "start, lighting, ignition" (SLI) batteries, industrial batteries, portable batteries, and stationary energy storage systems entering the EU market or produced within the EU.

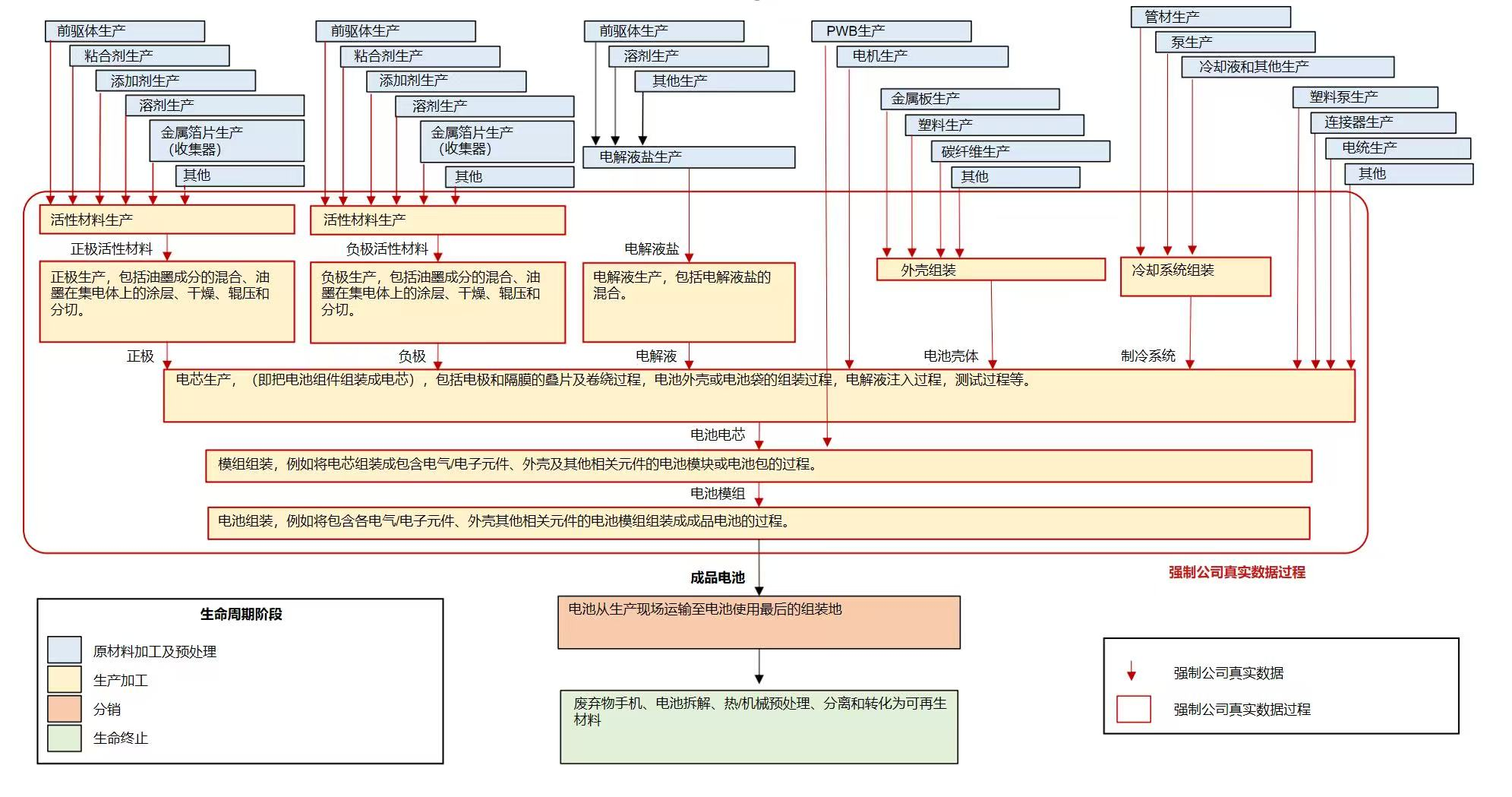

On April 29, 2024, the European Commission released a draft of EV battery carbon footprint calculation rules (Commission Delegated Regulation Supplementing Regulation (EU)2023/1542), aiming to provide supporting details for implementing all requirements under the new battery law, mainly detailing the methods and specifics of carbon footprint calculation and third-party certification. The following figure shows the system boundary of the battery carbon footprint determined by the draft.

(II) Sustainable Product Eco-design Regulation

With the growth of global environmental awareness and increased consumer willingness to purchase sustainable products, the EU Sustainable Product Eco-design Regulation (ESPR) was introduced. ESPR officially took effect on July 18, 2024, requiring almost all products entering the EU market to comply with eco-design requirements, introducing and systematically regulating Digital Product Passports (DPP). It mandates that related products entering the EU market must provide a full lifecycle green sustainability information dataset, aiming to promote product repair and circular use and enhance procurement and management decisions based on disclosed information across the value chain. Therefore, Chinese manufacturers will be obligated to ensure that the design and production of related products meet ESPR requirements while fulfilling compliance obligations and undergoing EU market supervision.

For battery products, the EU Battery Regulation includes a digital battery passport, comprehensively specifying the content of the digital battery passport (see Figure 2), applicable to all LMT batteries, industrial batteries over 2kWh, and EV batteries placed on the market or put into use.

Challenges and Risks for Green Export Enterprises

Challenges posed by EU EV battery carbon footprint calculation rules to relevant export enterprises include:

Strict Requirements for Upstream Data: Following the principle of upstream process data traceability, the draft requires battery manufacturers to use company-specific data when calculating the carbon footprint of products, mandating the use of company-specific data for calculating the "mandatory primary production processes"3 emissions of batteries. This means that battery manufacturers must collect raw data from suppliers rather than using carbon emission database factors, imposing stricter requirements on supply chain carbon data collection and management capabilities. For "non-mandatory important processes" and other processes, although battery manufacturers can use database data, the database must meet high-quality standards4, virtually excluding the possibility for export enterprises to use most domestic carbon emission factor sets.

Limited Conventional Transaction Methods for Green Electricity: When calculating the carbon footprint of electricity consumption, the draft stipulates the use of location-based accounting methods only, not accepting market-based electricity consumption portfolios. This means that battery manufacturers can only use the average emission factor of the Chinese power grid multiplied by electricity consumption for calculations, excluding common market-based transaction methods like green electricity trading5 and green power certificates (green certificates) generated carbon reduction benefits. Thus, battery producers can only reduce battery production carbon footprints through self-generated green electricity (such as distributed photovoltaics on-site) or other physical direct connection methods.

Restrictions on Emission Reduction During Battery Disposal and Recycling Phases: The draft specifies default scenarios for the battery disposal and recycling phases and requires battery manufacturers to use default scenarios for carbon footprint calculations in most cases; only under strict conditions and providing corresponding vouchers can enterprise-specific waste disposal data be used to reduce the carbon footprint impact of this phase. This regulation undoubtedly poses practical obstacles and demotivates export enterprises initially exploring the use of recycled materials and attempting to quantify corresponding emission reduction effects.

Additionally, the draft explicitly specifies the format and content requirements for battery product carbon footprint reports and mandates quantifying data quality levels (DQR) according to prescribed assessment methods. In terms of information disclosure, carbon footprint reports and related carbon emission information need to be publicly disclosed.

Main Challenges Posed by EU Battery Passport Information Disclosure Requirements to Relevant Export Enterprises Include:

Increased Risk of Data Leakage: Core data sources for product digital passports under ESPR originate from various stages of the value chain, involving aspects of ESG and carbon management, characterized by strong systematicness and sensitivity. Within the framework of the "Digital Europe Work Programme," the EU has established DPP special projects, relying on identification resolution networks, blockchain service infrastructure, public data spaces, and other new infrastructures to accelerate the construction of the product digital passport system. Full lifecycle data of China's exported products are closely related to industrial technology layout, especially industrial data in key competitive tracks such as new energy and consumer electronics, directly connecting to the EU system potentially causing extensive data leakage. How enterprises complete compliance with information disclosure while ensuring cross-border data security poses urgent challenges for China's information infrastructure construction and achieving international compatibility/recognition mechanisms for DPPs.

Increased Enterprise Management Costs: The EU product digital passport imposes new and higher requirements on manufacturing enterprises' product data aggregation, archiving, verification, and interaction. Firstly, in information management, the product digital passport involves large-scale data aggregation and interaction, necessitating corresponding software and hardware infrastructure, generating technical transformation costs. Secondly, in indicator compliance, the product digital passport involves numerous product conformity verifications, with domestic and foreign conformity assessment mechanisms unlikely to fully coordinate in the short term, resulting in cross-border monitoring and certification costs. Thirdly, in management compliance, the product digital passport involves multiple areas such as digitalization, green low-carbon, and internationalization, requiring specialized talent and governance structures, leading to operational compliance costs.

Carbon Information Disclosure and Management Practices Among Peers

Battery manufacturers and stakeholders have taken actions to systematically and efficiently manage related product carbon footprints and attempt to disclose battery passport information to address stricter overseas regulatory compliance requirements and alleviate the adverse effects of green barriers. Below, we summarize the carbon management and disclosure practices of representative battery manufacturers using CATL as an example.

New Technology/Product R&D: CATL incorporates production-side energy consumption, carbon emissions, material recycling, and other factors into research and conducts predictive life cycle assessments (LCA) for new technologies, coordinating the performance cost and environmental impact of technologies. Simultaneously, the company combines product carbon footprint, water pollution impact, soil pollution impact, and bio-toxicity impact indicators for predictive analysis, ensuring product compliance while achieving comprehensive environmental and carbon management.

Product Carbon Information Disclosure:

- In 2022, CATL reported the full lifecycle environmental data of its 280Ah LFP cells for energy storage based on ISO14025:2006 and successfully obtained an Environmental Product Declaration (EPD) compliant with EPD Italy007 and EN 50693:2019 classifications through the EPD Italy platform.

- In January 2023, under the framework of the Global Battery Alliance's (GBA) first pilot project, CATL issued the first concept validation for a battery product digital passport, recording the manufacturing history, chemical composition, technical specifications, and carbon footprint of three new energy batteries, including Tesla. As a member of GBA, CATL's EV battery information supplied to Audi was published on the GBA website (Figure 3).

- In November 2024, CATL's Shenxing battery and CTP battery passed the second round of pilot projects (Figures 4-6), both disclosing separate battery passports, with calculated carbon footprint (HMA) values of approximately 49kgCO2eq/kWh for both pilot projects. Although CATL's public carbon disclosure initiatives lead domestically among peers, there remains significant room for improvement in information granularity and transparency.

Value Chain Carbon Management: CATL employs supply chain audit tools to conduct a sustainable transparency audit program, identifying suppliers' performance and capabilities in energy management, climate change response, and other areas, actively conducting training and empowerment programs. Based on suppliers' current management status, CATL proposes sustainable development management targets and improvement requirements, including green electricity usage ratios, recycled material usage ratios, carbon emission intensity, and unit product energy consumption, and monitors suppliers' progress toward sustainable development performance targets through on-site audits, third-party agencies, and online meetings.

Global Battery Alliance Battery Passport:

The Global Battery Alliance (GBA) is an international organization initiated by the World Economic Forum and established in 2017. Currently, it attracts over 120 enterprises, governments, and non-governmental organizations, aiming to establish a sustainable, responsible, and equitable global battery industry chain by 2030.

GBA conceptualizes the battery passport as a framework to enhance transparency across the entire battery value chain, making electronic passports the digital twin of physical batteries and tracking full lifecycle information and sustainable development performance. In design, the GBA battery passport collects, exchanges, organizes, and reports trusted data between all lifecycle stakeholders regarding material origins, battery chemistry, manufacturing history, and sustainable performance, enhancing transparency across the global battery value chain based on standardization, comparability, and auditability.

In the future, GBA will promote relevant work based on the proof of concept for the battery passport: Firstly, a global reporting framework to manage the measurement, auditing, and reporting rules of ESG parameters throughout the entire battery value chain; secondly, a digital battery ID that includes information about ESG performance, manufacturing history, origin data, and data to extend battery life and enable recycling; thirdly, information system coordination to harmonize data reporting across the entire value chain into the battery passport; fourthly, a digital battery platform to collect, exchange, organize, and report data among all authorized stakeholders to advance sustainable value chains for power batteries and industrial batteries; fifthly, a battery quality seal to promote green consumption by consumers based on data reported to the platform.

Corporate Green Export System Solutions

Carbonstop provides comprehensive product carbon footprint and digital carbon management services (custom software services, SaaS) to help companies improve their carbon emission management and disclosure in operations and supply chains. It supports new energy manufacturers in enhancing their product/institutional carbon management and digitalization levels, helping related export-oriented enterprises comply with green policies and manage risks.

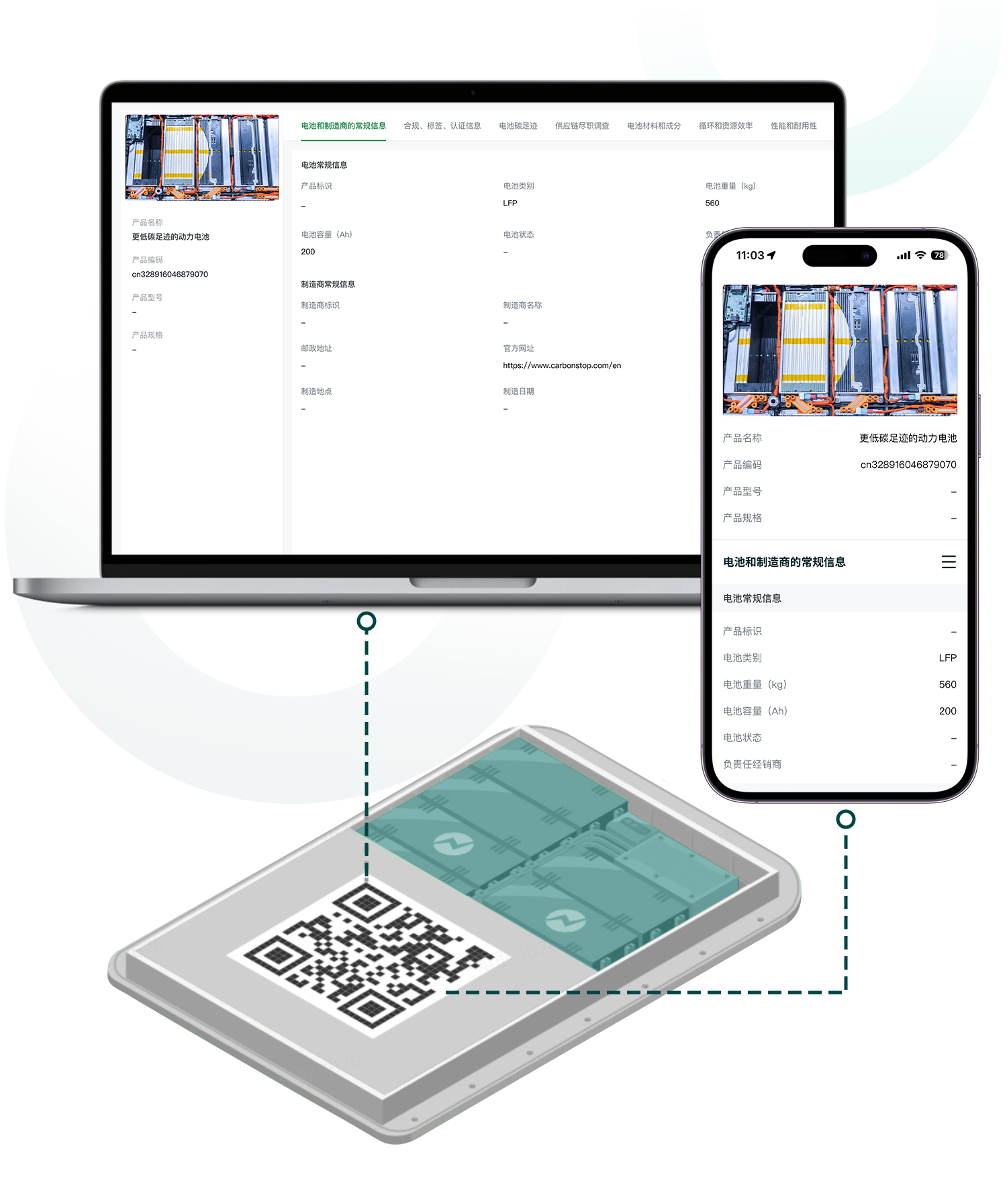

For battery and energy storage producers, we offer a full lifecycle one-stop solution covering eco-design of products, green and low-carbon production, sustainable supply chain management, information disclosure, and impact communication. We also assist companies in establishing long-term ESG risk management mechanisms and creating battery digital passports (Figure 7) that meet compliance requirements for exporting to the EU.

At the same time, we use digital systems to empower corporate carbon management, enhance the effectiveness of green procurement and supplier management, and help companies address carbon information disclosure compliance and potential risks associated with green exports through value chain data sharing, precise carbon emission accounting, and credible third-party certification. This enhances competitiveness and adaptability in international markets.

Carbonstop has extensive experience in carbon management, developing the CREOS carbon management methodology and successfully guiding companies through carbon management advancements and improvements. This ultimately leads to reducing carbon footprints at both the product and organizational levels, achieving full value chain carbon neutrality.

Notes:

1. Not only involves traditional product service export trade but also includes setting up production bases, R&D centers, or conducting cross-border mergers and acquisitions within the EU.

2. Includes textiles (especially clothing and footwear), furniture (including mattresses), steel, aluminum, tires, cleaning agents, paints, lubricants, chemicals, energy-efficient appliances, communications, and other electronic products.

3. The draft divides the EV battery production process into "mandatory primary production processes," "non-mandatory important processes," and "other processes." Among these, the mandatory processes requiring company-specific data include the production of cathode active materials, anode active materials, electrolyte production, casing manufacturing, thermal management system manufacturing, cell assembly and testing, and battery (module) assembly.

4. Database data includes secondary datasets and company-specific datasets, which must meet certain Data Quality Rating (DQR) requirements; for secondary datasets, their data quality assessment must meet certain Technological Representativeness (TeR) requirements.

5. The draft also does not recognize mainstream medium- to long-term electricity trading forms such as Power Purchase Agreements (PPA).